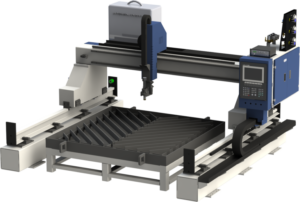

Plasma Cutting Machine Gantry Structure

Plasma Cutting

Saving of expensive metal sheet materials and saving of total cutting time is most important to increase the productivity and profitability. Trooper nesting and cutting software is the right answer to your this requirement. Trooper software will increase your programming efficiency, material utilization, cutting productivity dramatically.

Plasma :-

CNC controlled data communication to plasma power source thus cutting data are sent directly from the CNC controller to the plasma system (database)

Arc voltage height control with data connection and automatic communication

| Model | PL 2040 | PL 3070 | PL 30120 | PL 40140 |

| Working Area | 2000 mm x 4000 mm | 3000 mm X 7000 mm | 3000 mm X 12000 mm | 4000 mm X 14000 mm |

| Processing Material | Mild Steel, Stainless Steel, Aluminium, Galvanize | |||

| Plasma Source | Hypertherm 45amp / 65amp / 85amp / 105amp / 125amp / 200amp / 300amp / 400amp / 800amp | |||

| Motor and Drive System | AC Servo Motor (Japan) With Gear Box | |||

| Control System | 7″ display with high resolution, Industrial ARM7 processor chip, 2 axis controller, Storage capacity – 32MB | |||

| Transmission | X, Y axis – Rack and Pinion, Z axis – Ball screw | |||

| Nesting Software (optional) | Trooper 2d Cutting | |||

| Maximum Traveling Speed | 100 To 10,000 Mm/min | |||

| Torch Height Controller | Thc System Included For Accurate Torch Height Control With Anti- Collision | |||

| Air System | Clean, Dry & Oil Free | |||

| Air Inlet | 6 Bar (189 Ipm) | |||

| Input Voltage For Plasma Machine | 1 Phase, 230v, 50hz | |||

| Input Voltage For Plasma Source | 3 Phase, 420v Ac, 50/60 Hz | |||

| OxyFuel Attachment | No | |||

Leave a Message

Contact Info

Phone: 07314932301

Mobile: 9826394777 / 9826925333

Address :- Shop No. UG-50,Trade Centre 18, South Tukoganj,Indore

Mail :- sclcadcamsystems@gmail.com